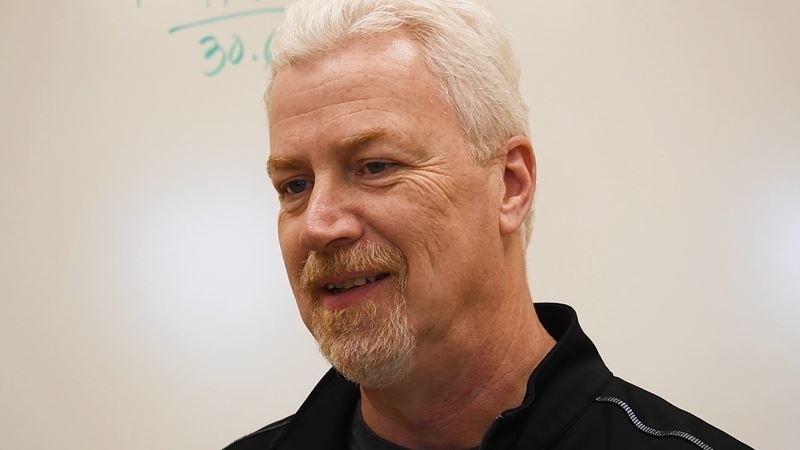

Eric Davis, training director at the Warren Electrical JATC, says safety is the main focus from day one for commercial and residential electrician apprentices.

Safety – both for employees and customers – is at the forefront of each electrical project our member contractors take on.

“Safety is a state of mind,” said Eric Davis, training director for the Warren Electrical JATC. “You have to want to work safe. Sometimes that means you have to take your time and think things through. We want everyone to go home from work with all the fingers and toes they went to work with.”

For apprentices at the Warren Electrical JATC, safety is the main focus from day one.

“Every apprentice gets a minimum of the OSHA 10 class,” Davis said. “Most apprentices also take an OSHA 30-hour class before they’re done.”

Being safe also means wearing the proper personal protection equipment, known as PPE, at all times.

“Everybody should be wearing a hardhat and safety glasses at least every day,” Davis said. “Some jobs require more PPE than that. Everything requires at least a hardhat and safety glasses.”

At member contractor “Joe” Dickey Electric, electrical preventative maintenance services have grown thanks to a partnership with CurrentSAFE®, which is available to homeowners and business owners.

“With us dealing with electrical, it’s obviously a very big concern for a lot of our customers,” said Eric Carlson, president of “Joe” Dickey Electric. “Usually when you have a problem with your electrical system, it usually relates to a fire.”

Using the latest technology that includes thermography testing, the Joe Dickey Electric EPM program can find potential electrical hazards in commercial, residential and industrial settings, offering same-day reporting.

“We want to make sure we’re finding those hazards early, so we don’t have any loss of life, loss of property or downtime with production,” Carlson said. “We’re able to perform a much cleaner report, and we have a support network that we’re able to use. We want to help our customers find their electrical problems.”

Carlson also stressed the importance of NFPA 70E compliance.

“It’s a huge determining factor to electrical preventative maintenance,” he said. “Before you always had to have a customer that was trying to be very proactive. Now with OSHA and NFPA 70E, this type of service is being mandated. There’s a six-step list to compliancy.”

With this partnership, Dickey is able to provide customers with a whole new level of service.

“We can be their NFPA 70E compliance contractor, not only offering them pipe and wire services, but also partnering with them on their safety,” Carlson said. “We want to make sure they’re able to provide a safe workplace for their employees, protect their property and make sure their business runs smoothly.”