NECA-IBEW Electricians stay at forefront of technology

As 2019 progresses, the rapid growth of technology will play a huge role throughout the electrical industry.

“The way projects are constructed and what’s in the projects changes daily and yearly,” said Jim Burgham, business manager, IBEW Local 64 in Youngstown. “Every time you see a new building go up, whether it’s a school or warehouse, they’re using the latest technology. Programmable controllers that have been around a long time are even more state-of-the-art now. can get on from home and actually fix projects or problems out in the field.”

Building automation and energy management are expected to be top trends this year.

“A lot of customers are requesting that, and we have a couple member contractors focusing on it,” said Jack Morse, business manager, IBEW Local 573 of Warren. “It’s also a part of our apprenticeship and training so our guys are ready for it. It’s really taken off and become a good portion of our work.”

At member contractor VEC, Inc., one of the biggest priorities is implementing new technology that improves performance on jobsites.

“One of the first things that comes to mind is what we can put in the hands of our field labor employees,” said Mike Reiser, project manager, VEC, Inc. “As technology increases, and better tools become available, we see the results of putting these tools in the hands of our workforce and enabling them to work more efficiently and safely.”

And it all starts with using state-of-the-art software to bid on potential projects.

“People automatically think technology is just field-related,” Reiser said. “Our bidding software allows more efficient ways to look at things, different ways to allocate hours and material and the way we organize bids. We look at things from a more competitive manner.”

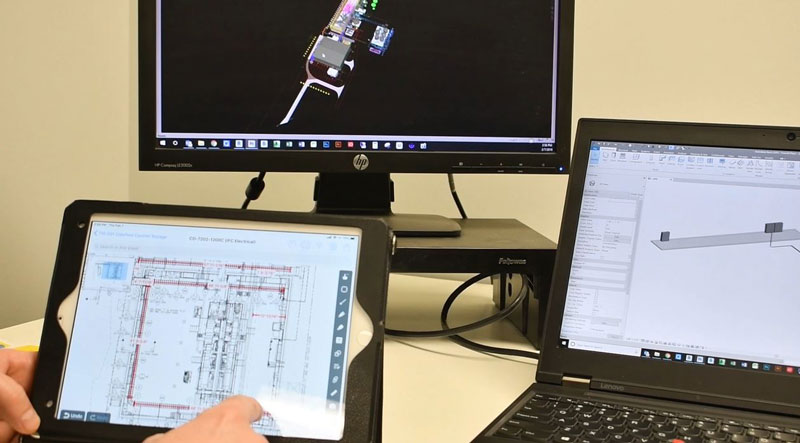

VEC also employs tablet technology on the jobsite to improve efficiency and accuracy.

“We have quite a few iPads, almost 70, out in the field,” said Nicholas Barbush, director of project integration, VEC, Inc. “We’re able to utilize a couple applications to streamline communication and efficiencies between the office and the field.”

One of these applications, PlanGrid, helps workers analyze drawings and reference details at their fingertips rather than having to go back to a trailer to look at blueprints. 3D models can also be uploaded and viewed on the iPads using BIM 360.

“Using BIM 360, we can embed critical information into different model pieces inside of the virtual environment,” Barbush said. “We can click on a cable tray and list specific notes, elevation, length and other information that needs to be known about a particular piece of equipment.”

In addition to the tablet technology, Reiser noted the use of thermal imaging cameras.

“We’re able to quickly go out and maybe identify some anomalies within electrical equipment, and use it as a preventative, predictive piece of equipment. We can see the problem ahead of time, before there’s a blow up or malfunction, and notify the customer,” he said.

With ever-growing technology also comes the need to maintain active training for apprentices and journeymen electricians.

“We always pride ourselves on staying educated and trained,” Burgham said. “As technology evolves and new methods of construction come into effect, we just continuously train and change our training. You can’t wait until a project is here to decide what training you want, so training is always evolving.”

NECA-IBEW Electricians is an association of IBEW Local 64 (Youngstown), IBEW Local 573 (Warren) and signatory electrical contractors in the Mahoning Valley.